For practical purposes, this type of computer-aided manufacturing (CAM) is normally performed layer by layer with typical layer thicknesses ranging from 15 to 500 μm. The coordinates of the virtual object and digital slices are then used to steer the motors, which control the position of the building device or the 3D-dispenser orifice, respectively. Objects with overhanging portions (i.e., the coffee mug handle) are designed with temporary support structures to prevent collapse during the build process. In the first step, CAD is used to create a virtual object, which is then digitally sliced. Although a coffee mug is not very complex, it provides a convenient object to demonstrate the concepts of AM ( Figure 1). In this work, the terms “additive manufacturing” (AM) and 3D printing are both used to describe the same general manufacturing principle.ĪM allows the production of 3D structures with high shape complexity. While “additive manufacturing” is preferred by most engineers, the term “3D printing” is far more common particularly in the popular media. In literature, the terms additive manufacturing, rapid prototyping, layered manufacturing, solid freeform fabrication, 3D fabbing, and 3D printing are used more or less synonymously. Whereas conventional fabrication is governed by processing constraints related to industrial mass production, AM is inherently agile enabling faster turnaround on design and manufacturing of customized objects tailored to meet the demands of individuals and specific applications. In the same way that the development of digital 2D printing together with desktop publishing has revolutionized communication and information technology, the development of AM technologies in conjunction with the “internet of things” has the potential to revolutionize computer-guided fabrication of both complex objects and multifunctional materials systems. Today 3D printers are commercially available for less than $500, enabling desktop fabrication of 3D objects even at home.

AM allows the production of customized parts from metals, ceramics, and polymers without the need for molds or machining typical for conventional formative and subtractive fabrication. Unparalleled by metals and ceramics, polymer-based AM plays a key role in the emerging AM of advanced multifunctional and multimaterial systems including living biological systems as well as life-like synthetic systems.įirst introduced during the 1980s to serve the highly specialized needs of model making and rapid prototyping (RP), additive manufacturing (AM) alias 3D printing has emerged as a versatile technology platform for computer-assisted design (CAD) and rapid manufacturing. Selected applications demonstrate how polymer-based AM is being exploited in lightweight engineering, architecture, food processing, optics, energy technology, dentistry, drug delivery, and personalized medicine. Aspects of polymer design, additives, and processing parameters as they relate to enhancing build speed and improving accuracy, functionality, surface finish, stability, mechanical properties, and porosity are addressed.

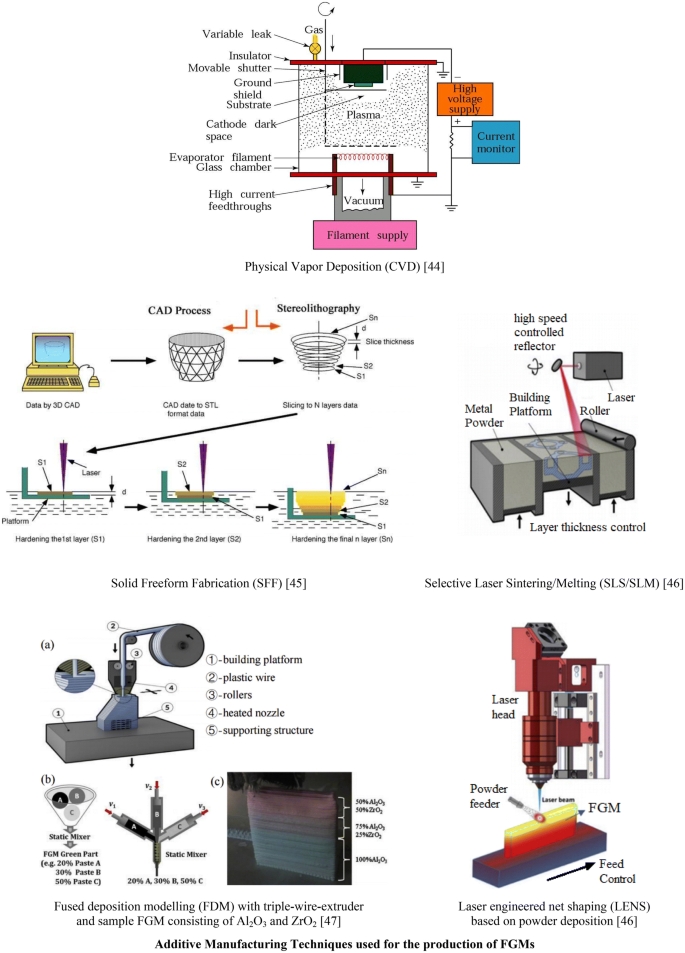

The range of polymers used in AM encompasses thermoplastics, thermosets, elastomers, hydrogels, functional polymers, polymer blends, composites, and biological systems. AM techniques covered include vat photopolymerization (stereolithography), powder bed fusion (SLS), material and binder jetting (inkjet and aerosol 3D printing), sheet lamination (LOM), extrusion (FDM, 3D dispensing, 3D fiber deposition, and 3D plotting), and 3D bioprinting. Because polymers are by far the most utilized class of materials for AM, this Review focuses on polymer processing and the development of polymers and advanced polymer systems specifically for AM.

The ongoing transition from rapid prototyping to rapid manufacturing prompts new challenges for mechanical engineers and materials scientists alike. AM enables decentralized fabrication of customized objects on demand by exploiting digital information storage and retrieval via the Internet. By digital slicing of CAD, 3D scan, or tomography data, AM builds objects layer by layer without the need for molds or machining. Additive manufacturing (AM) alias 3D printing translates computer-aided design (CAD) virtual 3D models into physical objects.

0 kommentar(er)

0 kommentar(er)